Dynamic racking systems

Our dynamic racking uses a modular approach that can significantly increase storage capacity and streamline the order/picking process.

OHRA dynamic rack systems – a worthwhile investment

While the purchase cost of a dynamic rack system is slightly higher than a conventional racking system, the benefits will soon pay for themselves. We can cater to all your dynamic racking needs, ranging from cardboard flow racking to heavy-load pallet flow racking, and can design modules that suit your location and your budget.

OHRA dynamic rack system advantages

- Modular components give you full flexibility

- Racks can be adjusted to suit the goods stored and picking process

- Wide range of modules available

- Shortens travel routes and speed-up order-picking

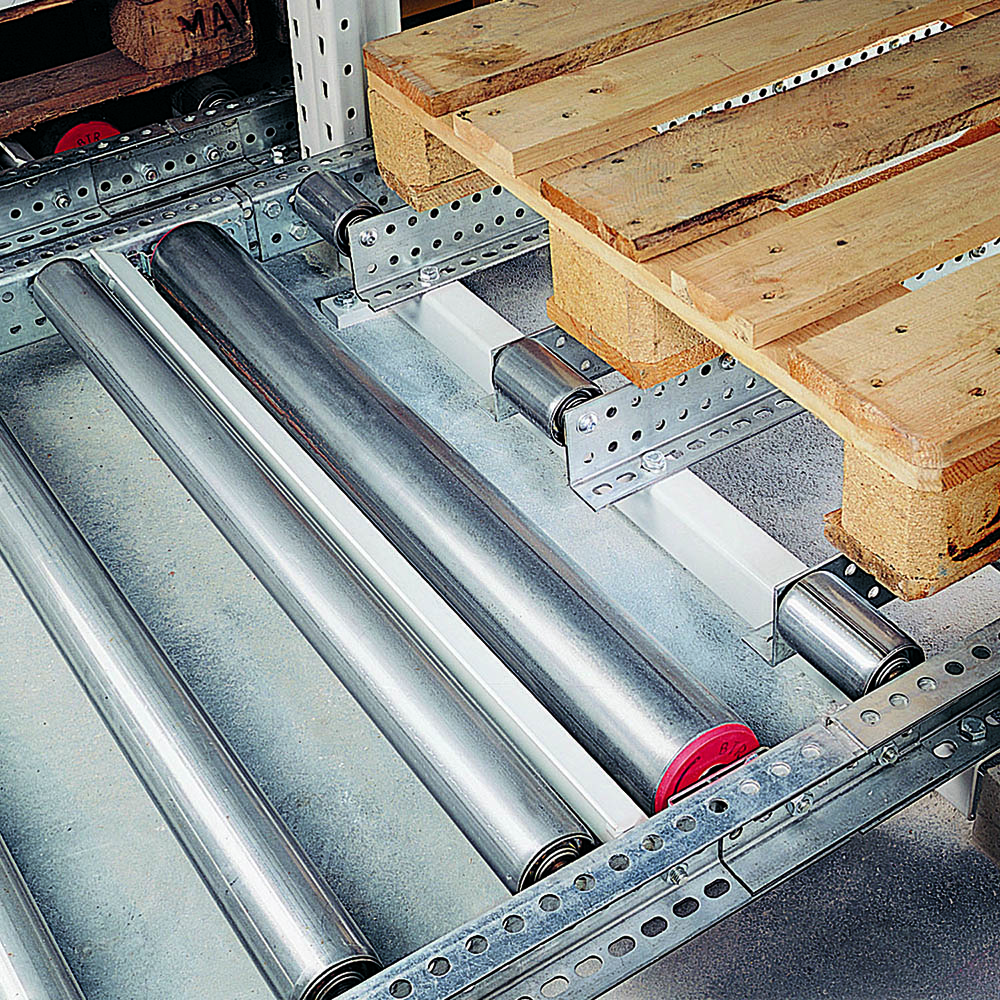

Pallet flow racking

Pallet flow racks are a highly compact method for first-in-first-out storage and picking. Our pallet flow racking system and uniform pallets ensures the maximum surface area is used and a high degree of filling is achieved. The smooth roller system has integrated brake support rollers so the product's own weight moves it to the removal position. The pallet separation unit on the removal side ensures safe handling.

OHRA pallet flow racking advantages

- Modular components give you full flexibility

- High load-bearing capacities and durability

- Safe handling through pallet separation

- Suitable for all smooth-running surfaces

- Shortens transport routes and speeds up FIFO order-picking

Order-picking flow racking

Our order-picking flow racks are similar to our pallet flow racks, but are better for cardboard or plastic boxes suitable for transport on roller conveyers. This makes them the best option for order-picking of regular turnover (medium-moving items) and high turnover (fast-moving items). Firt-in-first-out means stored goods are transported to the removal position by their own weight, ready for order-picking, and refill aisles are separated.

OHRA order-picking flow racking advantages

- Modular components give you full flexibility

- Individual plastic rollers with steel shafts can be loaded up to 6kg

- Suitable for cardboard and plastic boxes

- Shortens transport routes and speeds up FIFO order-picking

Push-back racking – trolley systems

Push-back or trolley systems are a great space-saving storage option based on the last-in-first-out principle for product batches of the same type. Our push-back trolley system give you storage depth of up to 6 pallets, without any direct contact with the goods.

OHRA push-back racking advantages

- Modular components give you full flexibility

- Storage depths of up to 6 pallets

- No-contact trolleys are suitable for sensitive pallet goods

- Shortens transport routes and speeds up LIFO order-picking

Push-back racks – roller conveyor systems

If you need greater storage depth - of up to 10 pallets - our roller conveyor systems will do the job. Our roller conveyors have a lower building height than push-back racking and because of the high push force required to move the pallets, these systems are particularly suitable for non-pallet-sensitive goods.

OHRA push-back racking advantages

- Modular components give you full flexibility

- Storage depths of up to 10 pallets

- Ideal for non-pallet-sensitive goods

- Shortens transport routes and speeds up order-picking